Design

A collection of plans and images that outline the design and fabrication of all auxiliary components used to facilitate the physical and material research of 'Human Systems of a Structure'.

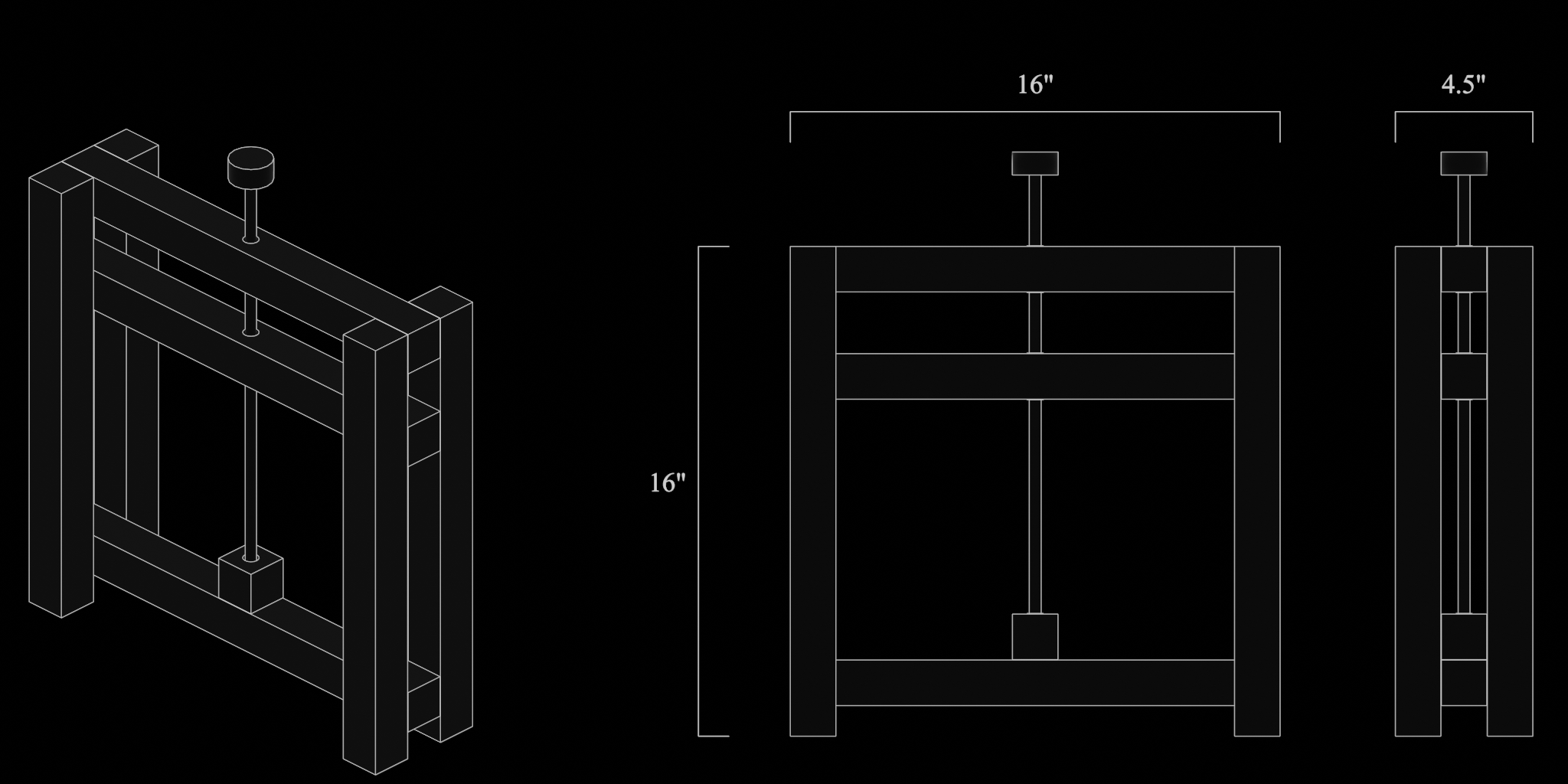

The Press (3in Cube)

From conception, we found that the trajectory of the physical research was dependent upon sourcing a specific set of materials that when combined, would fulfill characteristics and behaviors needed to visually describe the work. It was crucial that the material was both structural, and susceptible to deterioration from human interaction. Due to logistical factors such as safety regarding prolonged skin contact, reusability, and a particle size small enough to hold clear detail, we began experimenting with a base of fine aggregate (limestone sand), and a hydrophilic powdered clay to act as a binder. The use of both Bentonite and Kaolin clay were introduced in various ratios with the sand, all as a means to study the differences in durability under measured amounts of pressure. Due to the comparative sets of data drawn from both types of clay mixtures, Bentonite was proven to be more consistent as an added binder.

'The Press' was designed in order to gather a set of data for the variations in the compositional make-ups. Outfitted with a scale to measure the force compressing the substance in the form of a 3in cube, it functioned as a tool to conduct repeated testing on a small scale basis.

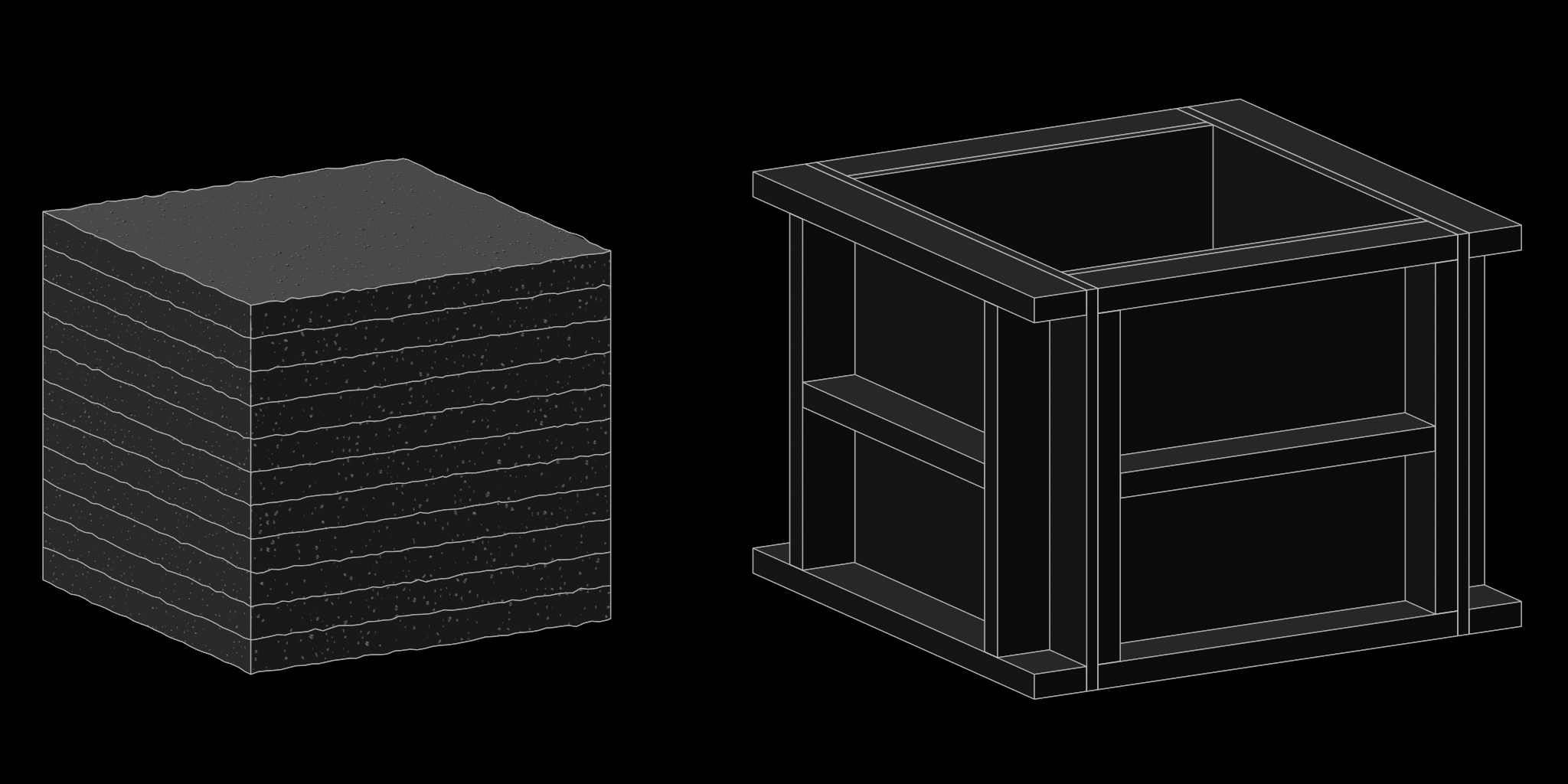

2ft Cube

The 2ft Cube was designed to continue our material research. In contrast to the 3in cube models, it was important for us to draw off of an existing real world method that would aid our ability to test the materials' relevance to a human scale. We referenced the practice of forming rammed earth structures, in which formwork is fabricated to contain the dimensions and volume of a compacted material. The degree of compaction is controlled by tamping the material in layers of measured depths.

Creating 2ft Cube models was a routine practice that allowed us to test the level of both permanence and impermanence through repeated transfers of weight over the form. This process was a way to observe and compare different compositions of material. A total of 4 batches were mixed and tilled, starting with a control of pure limestone sand, followed by three batches with consecutively increasing amounts of Bentonite clay. Other implemented variables that effected the cubes' durability were saturating the material with water, and tamping layers into different depths of either 4 or 2 inches. We were able to accurately measure added material based off of lines inscribed in one inch increments on the inner surfaces of the formwork.

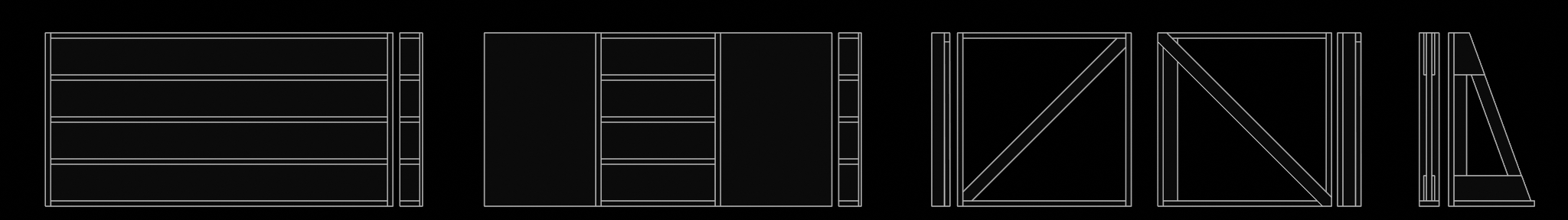

Formwork Components (exploded view)

Creation of a 2ft Cube

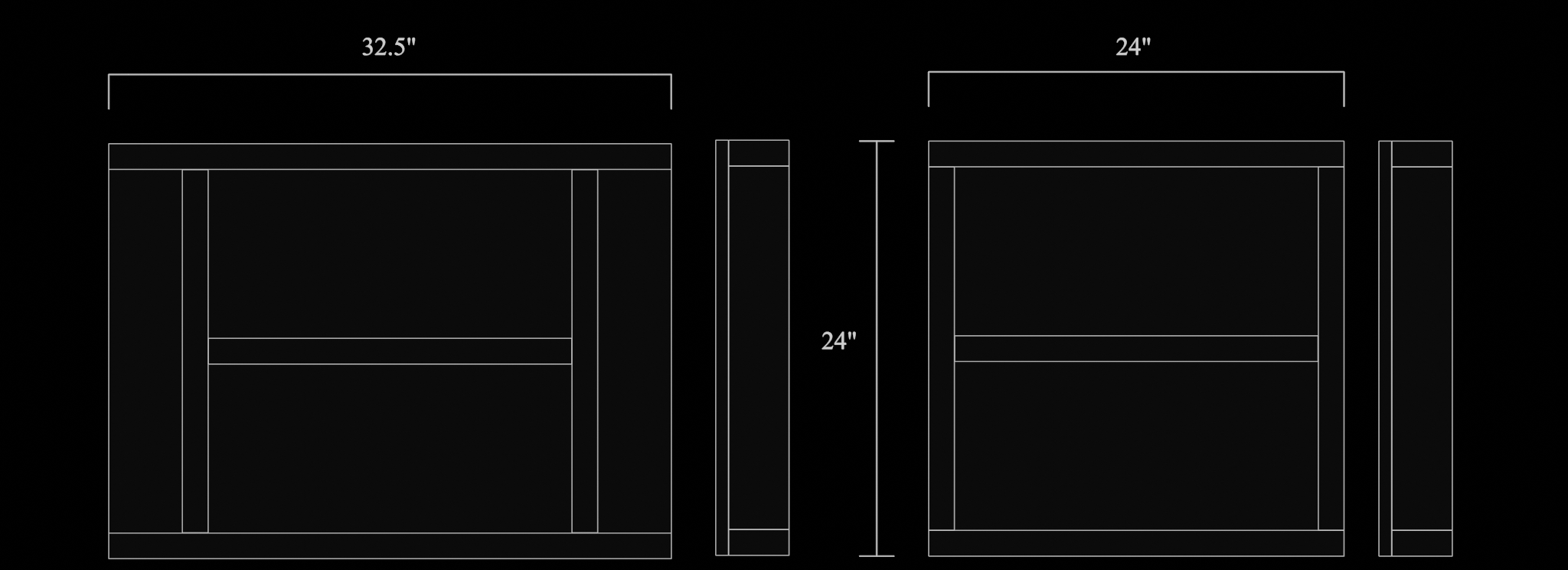

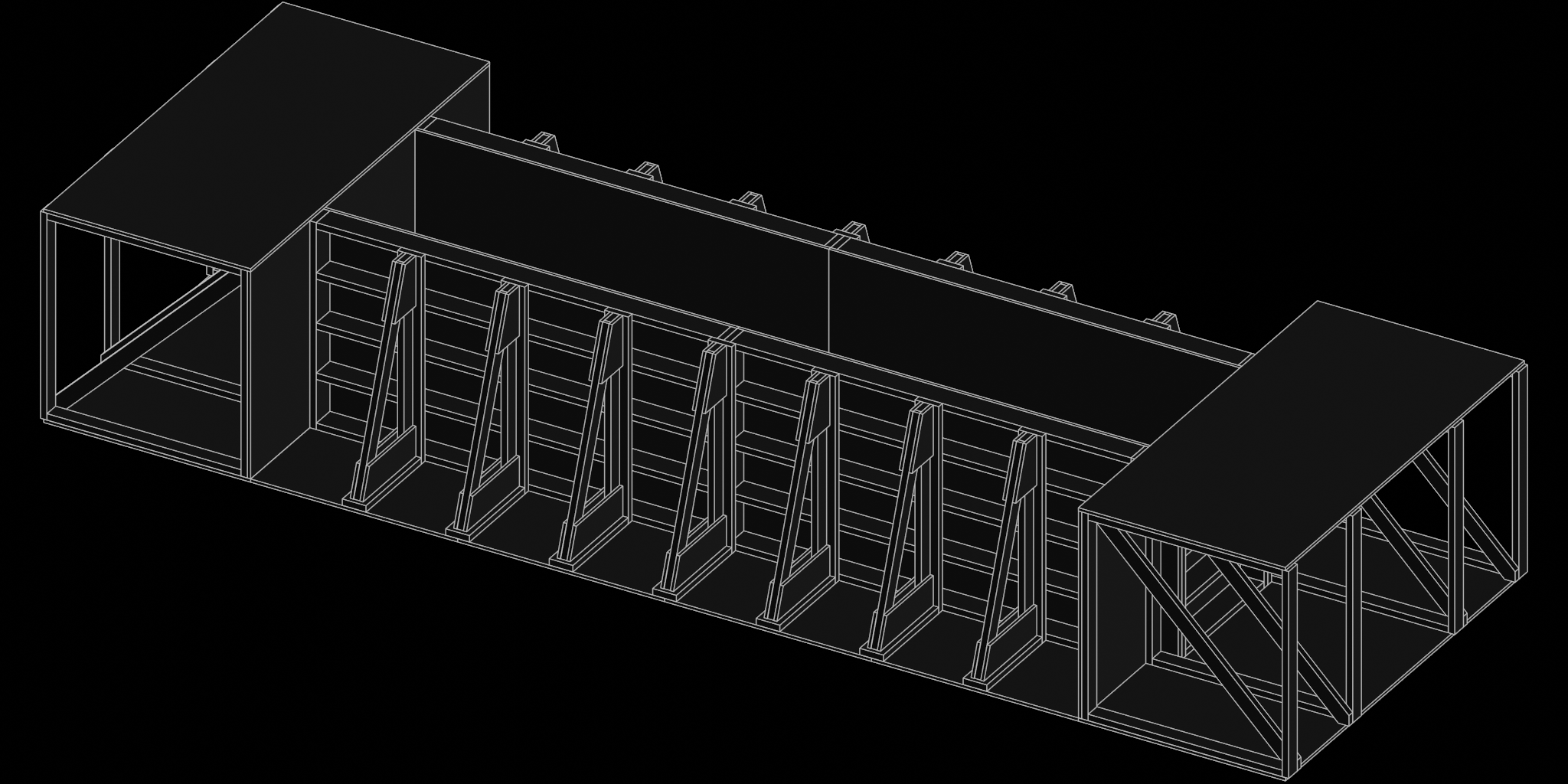

Span

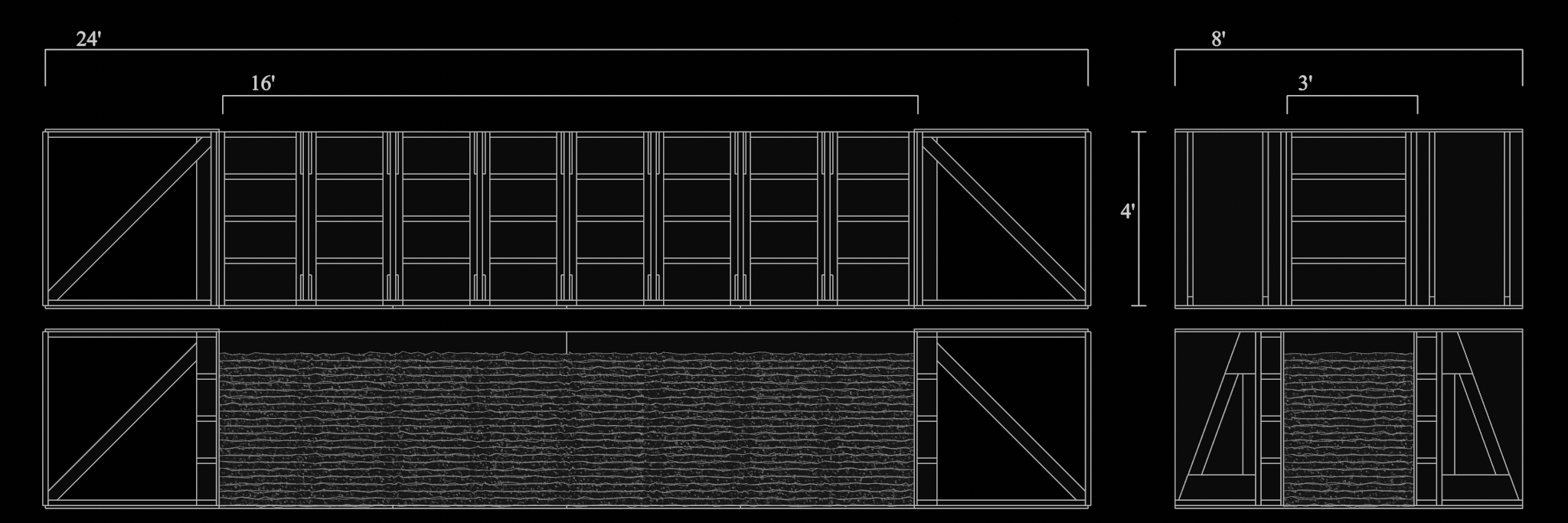

In order to facilitate fundamental themes - timescale, permanence/impermanence, and reactive behavior - from within the concept of 'Human Systems of a Stucture', it was vital that the material was compositionally described by a functional, architectural form; designed to span a distance of 16ft, with a 3ft width, and a 4ft depth.

The increased mass of substance that was needed to fully materialize the Span, was reliant on formwork fabricated to withstand considerably greater forces involved compared to previous models. In contrast to the temporary components of the formwork, two permanent perpendicular platforms provided structural support for the material, while also acting as compositional boundaries. These external surfaces allowed for movement to transition onto and off of the span.

A total of twenty-eight components, consisting of five unique designs made up the formwork in its entirety. On their own, these components served unique purposes, that when assembled, harmoniously worked together to carry out the processes of filling and tamping the material to create the Span. The most internal components of the formwork being four 4x8ft plywood panels, joined together in conjunction to the perpendicular platforms and bounded the dimensions of the span. For the panels to resist bending, and to remain rigid under the dynamic forces involved with the compaction of the material, each side was reinforced by seven buttresses, all anchored to the ground to provide adequate compressive strength. Like the 2ft Cube model, these panels also had lines inscribed in one inch measurements to act as a guide for adding material.

Elevation / Section Plans

Formwork Components (exploded view)

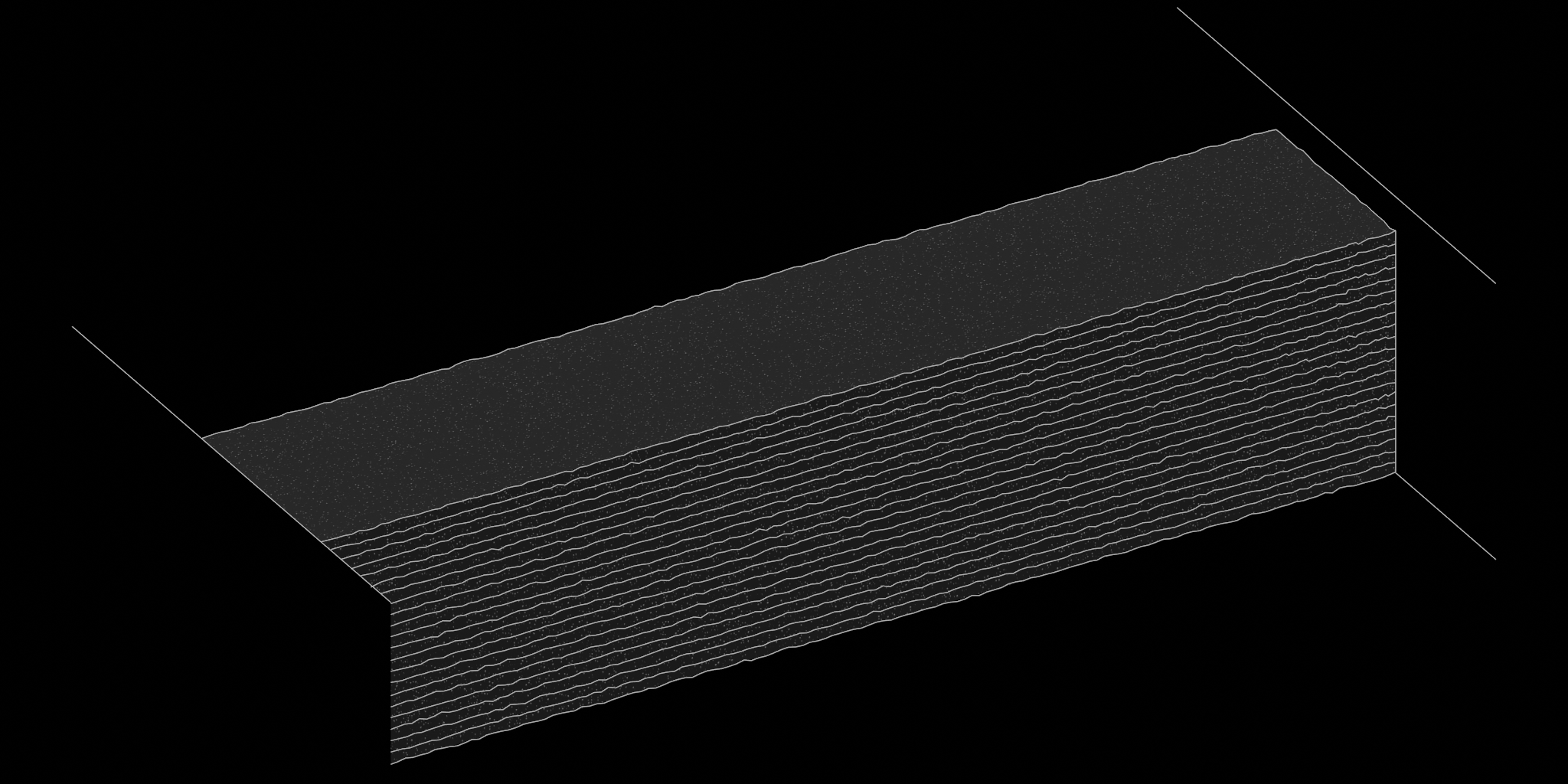

'16ft Span, 2020' consisted of 92.5% limestone sand, and 7.5% Bentonite clay. Approximately 8 cubic yards of total materials were mixed in small batches that were continuously processed and saturated through two cement mixers.

The process of filling the formwork in layers with a desired depth of 2in, required first adding even amounts of material in 3in layers, then tamping until 1in of compaction was achieved.

The space in which housed the entire fabrication and assembly of the Span, (and later the repeated documentation of physical processes), was a temporary outdoor enclosure constructed to isolate the work from variating environmental conditions. To counteract the uneven ground inherent to the Span's siting, we constructed an array of plywood panels to create a flat and level surface for the formwork to be assembled on and anchored to.

Fabrication & Assembly of Formwork

Mixing Material

Filling & Tamping Material / Removing Formwork

All components are modular by design to allow for expandability of the formwork, granting ourselves the creative freedom and opportunity to explore ideas of physical behavior at a larger scale.